SMTL are able to test the following characteristics of surgical gowns and drapes to BS EN 13795:2015+A1:2013 - Surgical drapes, gowns and clean air suits, used as medical devices for patients, clinical staff and equipment. General requirements for manufacturers, processors and products, test methods, performance requirements and performance levels.

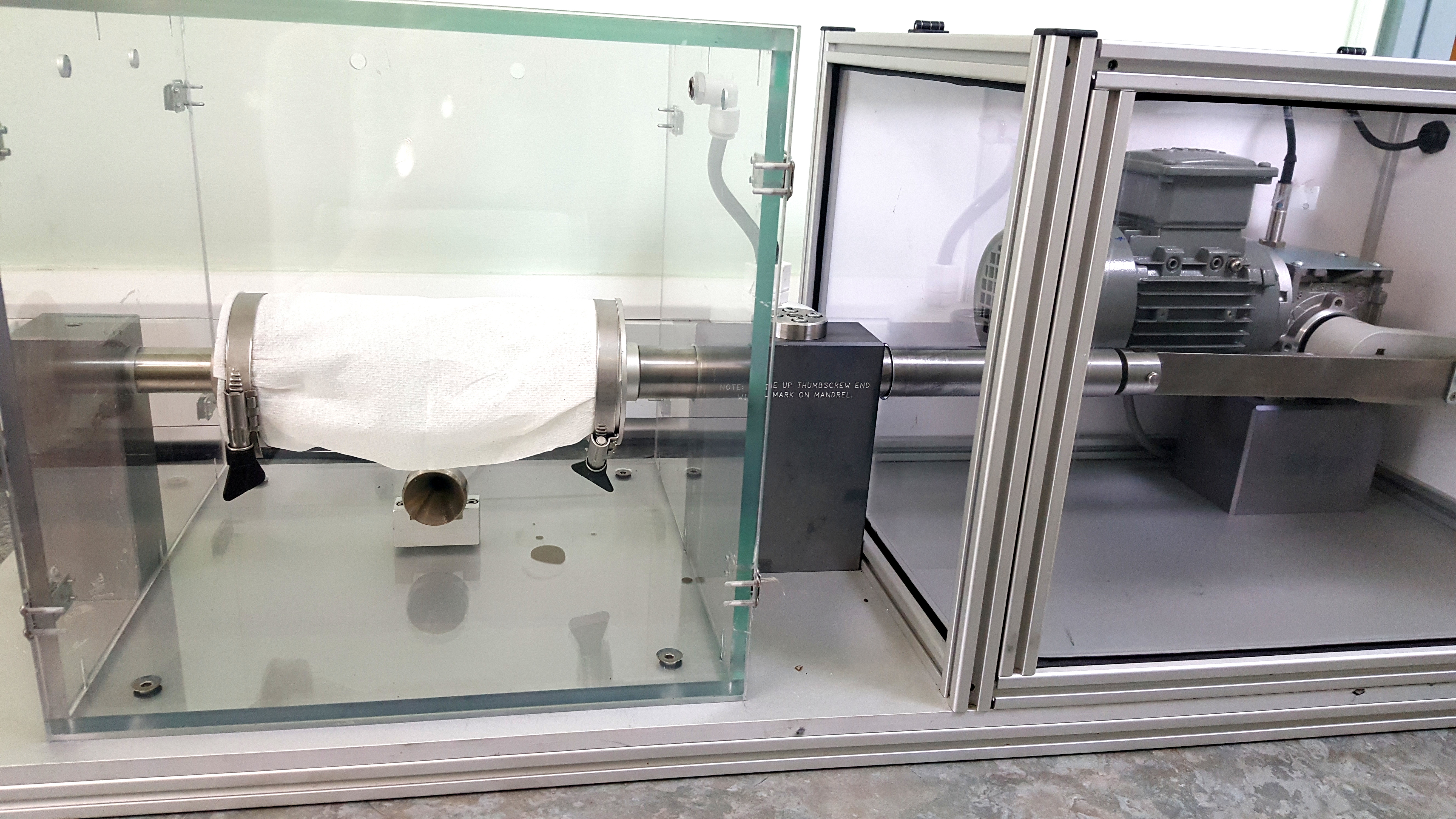

EN ISO 22610 - Wet penetration testing

In this test, the sample is tested to determine the resistance to wet bacterial penetration using the moving finger apparatus. The agar plate is incubated for 48 hours at 36°C and the total number of colonies on the surface of the plate are counted.

The estimated bacterial challenge (T) is calculated and compliance with the performance requirements determined.

The current version of 22610 is under review and when published will go into immediate revision as the round-robbin testing showed significant variation. If you require this testing we recommend you discuss it with us prior to commissioning any work.

EN ISO 22612 - Dry penetration testing

In this test, a portion of talc contaminated with a known number of Bacillus subtilis (B. atrophaeus) spores are poured onto the test piece inside a container. A container without the contaminated talc is used as the control. An agar plate is inserted into the base of the container below the test piece. The platform supporting the container is vibrated for 30 minutes by a pneumatic ball vibrator. Any talc that has penetrated through the test piece will be captured by the agar plate. The agar plate is then removed and incubated for 24 hours at 35°C and the total number of colonies on the surface the plate are counted.

The mean bacterial count is calculated and compliance with the performance requirements determined.

EN ISO 11737-1:2006 - Microbial cleanliness - Bioburden Testing

In this test, the number of viable micro-organisms recovered from the surface of the test sample is determined and estimated bioburden is calculated. Compliance with the performance requirements is determined.

EN ISO 9073-10 - Particulate matter & Linting

In this test, the samples is formed into a tube and placed onto the circular plates of the Gelbo Flex flexing chamber to which a particle counter is connected. The flexing unit is set to run 10 consecutive 30 second counts for each test piece. Background particle counts are performed prior to the test piece being mounted onto the flexing unit plates, and these are used to determine the final count of the corresponding test piece. Particle counts for size range 3μm to 25μm are calculated as particles of this size range are considered to be capable of carrying microorganisms.

The Index for Particle Matter (IPM) and the Coefficient of Linting are calculated and, compliance

with the performance requirements determined.

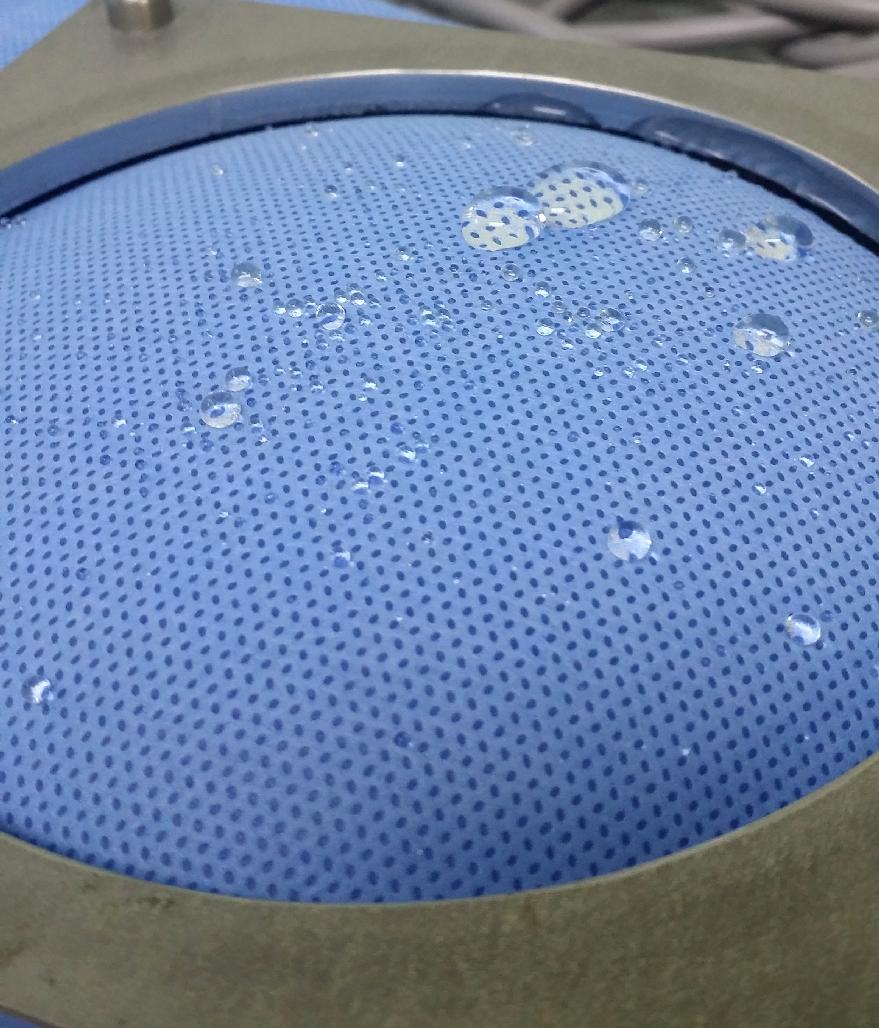

EN 20811 - Resistance to liquid penetration

In this test, the specimen under test is clamped so that the outer surface is subjected to a steadily increasing pressure of water from below the sample, at a rate of 10±0.5cm of water per minute. This testing is performed under standard conditions until penetrations occur in three distinct areas of the test material.

The pressure at which the liquid penetrates the fabric at the third place is noted, and compliance with the performance requirements are stated.

EN 29073-3 - Tensile strength

In this test, samples are tested in a wet and dry state at a 90 degree orientation to one another. The sample is placed into the grips of a tensometer and extended,

The mean tensile strength in each direction are calculated and compliance with the performance requirements determined.

For further information or to obtain a quote, please contact SMTL